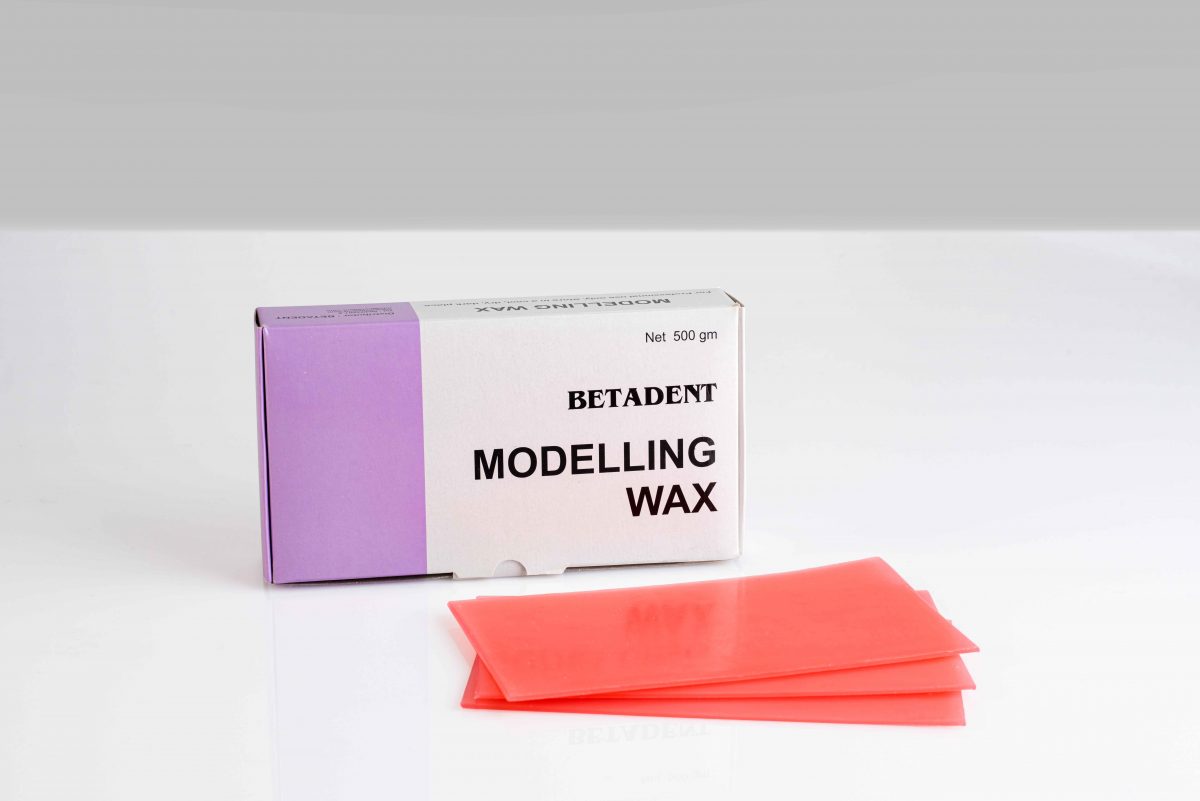

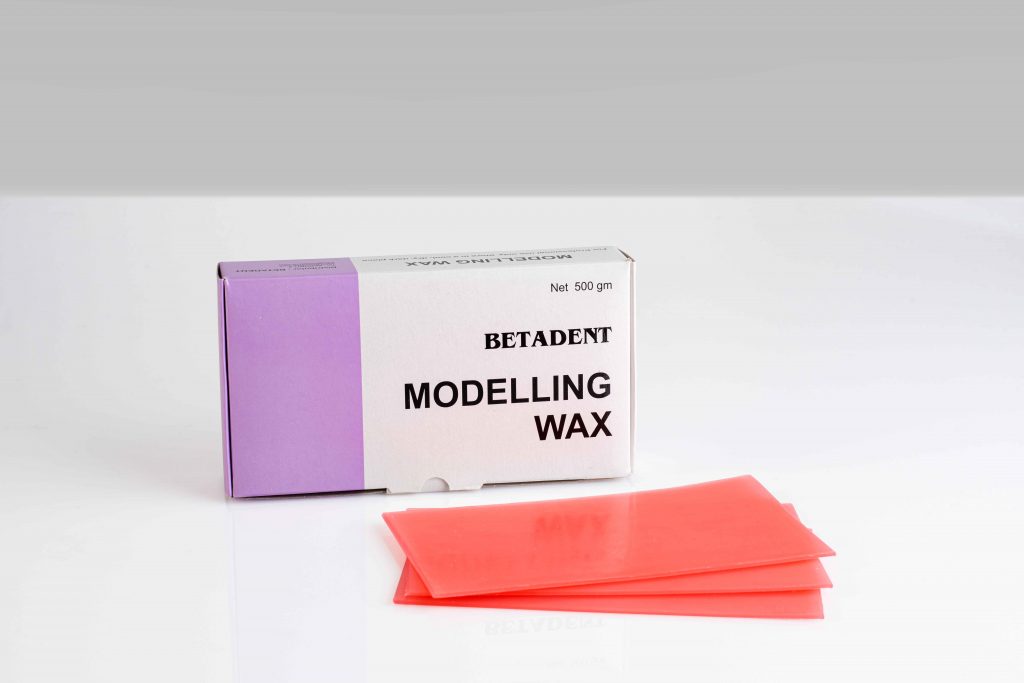

Wax Sheet (pink)

A combination of Paraffin, Microcrystalline and organic additives with a melting point of less than 5%. It is used for biting, modeling, arranging teeth on articulators and making prosthesis. Beta wax is easily formed during modeling and is resistant to temperature during operation and is produced in accordance with ISO 12163 standard

Application

For arranging artificial teeth on the casts, making dental prosthesis,

Modeling of partial dentures and removable prosthesis

Each sheet to make a maxillary and mandibular tooth

Product advantages

Excellent strength

Proper resistance and no cracking and fragility

Preservation of shape, modeling and no change of dimensions

Package:

500 g

Color :

Pink

arabic

arabic  فارسی

فارسی  Turkish

Turkish